PVT Tests Simulation (CCE, DL, CVD, Separator)

CCE (Constant Composition Expansion / Constant Mass Expansion) Test

To optimize the exploration and production from oil and gas fields, the reservoir fluid samples are taken and sent to the laboratory for a series of tests to gain the knowledge of producing best quality products in a most economical way under the changes of pressure and temperature of the reservoir. For example, it is essential to understand at what conditions the initial one-phase fluid splits into two phases and the compositions and the properties of each phase, etc. Such tests are called PVT tests and the properties PVT properties which usually are expressed as functions of pressure and temperature.

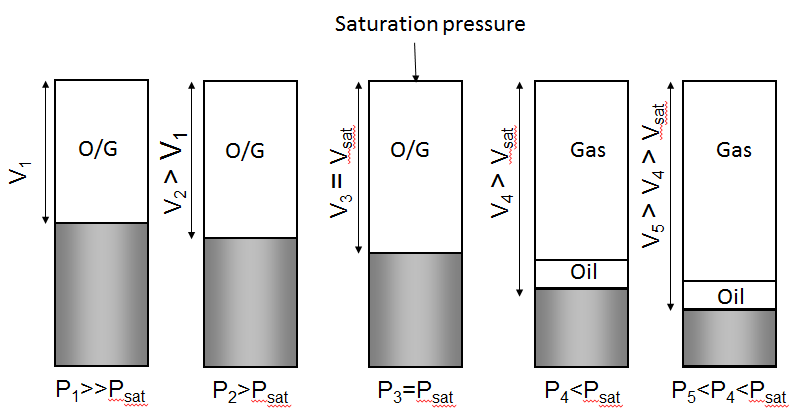

Once the compositions are determined at the laboratory, the CCE test is usually the first undergo test for either conventional oil or gas condensates. The test starts from the pressure higher than bubble point pressure at the reservoir temperature, and gradually decreases the pressure (hence the volume being expended at constant composition). The bubble point or dew point and the fluid properties changed with pressure and temperature are obtained from the test (see the schematic diagram).

This module of cloud computing is the process simulation of the CCE teat by the laboratory and can also be used to make a plan for a test workflow and an estimate of the test results.

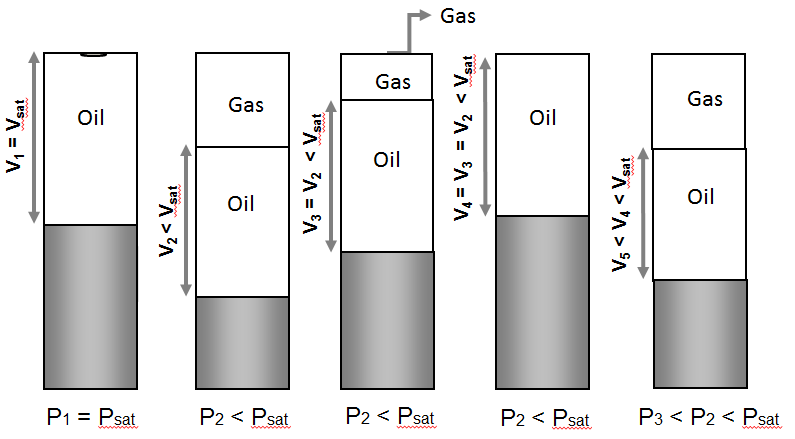

DL (Differential Liberation) Test

The DL test starts from the bubble point pressure (for conventional oil) or dew point pressure (for gas condensate), and gradually decreases the pressure at a constant temperature. The volumes of the oil and the gas at each step are measured and the depleted gas is collected. Like CCE test, the purpose of the DL test is to understand the phase behavior and the PVT properties of the reservoir fluid at the reservoir conditions. It is also to obtain the information of the oil volume at the reservoir conditions as compared to that at the standard conditions, i.e., the oil formation volume factor, Bo and the gas formation volume factor, Bg.

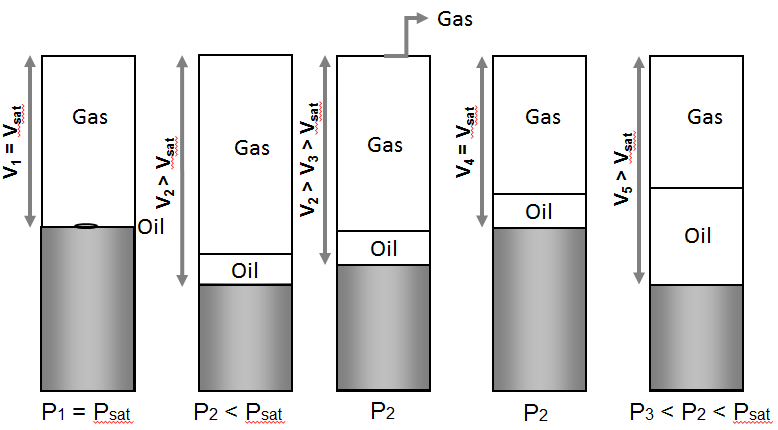

CVD (Constant Volume Depletion) Test

The CVD test starts at the dew point pressure of the gas condensate, and measures the saturation volume at the dew point, Vsat. As the pressure decreases, the volume increases to form the gas-oil two phases. The gas is depleted from a valve at the top of the cylinder to keep the total volume of the two phases equal to the saturation volume at a constant pressure (see the schematic diagram). The percentage of the depleted gas as to the original gas is measured as well as the percentage of the liquid dropout of the liquid volume as to the saturation volume.

The PVT properties of the gas condensate or the volatile oil as they may change with each stage in the productions are obtained.

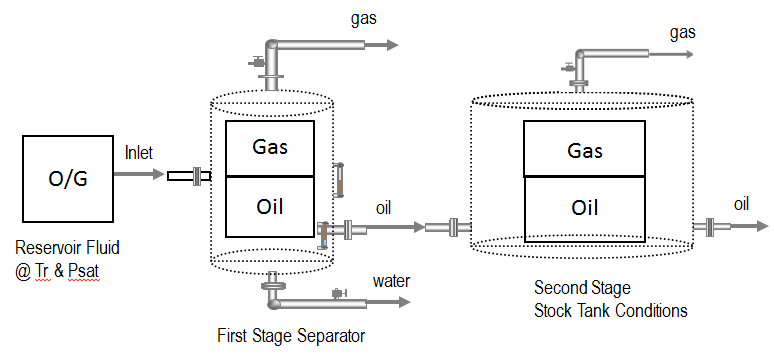

Separator Test

The objective of the separator test is to optimize the amount of oil produced at the surface. The test is carried out for either oil and gas condensate in single or multiple separators with the last stage at atmospheric pressure and temperature.

A sample of reservoir fluid is placed in the laboratory cell and brought to reservoir temperature and bubble point pressure. Then the oil is expelled from the cell to the next separator stage while the gas is let out and transferred to standard conditions. The process is repeated until stock tank conditions are reached. The solution GOR and the oil formation volume factor, Bo are measured in the test.