Contamination Analysis of Reservoir Fluids by OBM

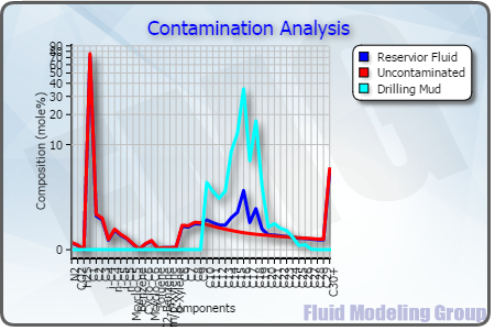

The oil-based muds (OBM) are commonly used in the drilling process of crude oil due to its resistance to high temperature and corrosion, good lubrication and least to formation damage. However, the samples taken from the underground after the well completion are often contaminated by the OBM which fail to represent the compositions and properties of the original reservoir fluids. It is, therefore, necessary to determine the contamination degree of the samples and to correct the PVT properties that are measured based on the contaminated samples, such as, saturation pressure, GOR, viscosity, density and formation volume factor, etc. In general, the compositions of the “clean samples” appear to follow a certain distribution pattern which can be used to determine the contamination of the fluid samples.

There are two methods to determine the contamination for a given sample: the Subtracting Method where the composition of the OBM is known; and the Skimming Method where the composition of the OBM is unknown.

Once the contamination is determined, i.e., the compositions of the “clean sample” are obtained, the correction of the PVT properties can be done following the procedures below:

- Performing the characterization using a couple of pseudo-components to represent the OBM (see Characterization of End Fraction in Reservoir Fluids);

- Creating a “new oil sample” to include the pseudo-components;

- Tuning the EOS model to match the measured the PVT properties based on the contaminated sample;

- Predicting the PVT properties of the “clean oil sample” (setting compositions of the pseudo-components to zero) and comparing them to that of the contaminated oil sample.